-

Call us : +8613400713026

-

E-mail : info@doolincm.com

Call us : +8613400713026

E-mail : info@doolincm.com

Bucket shims of wide-rim ring are known as machinery bushings,the shims have an oversized OD to create bushing surface for reducing wear between moving parts.They are widely used in bucket pin bushing etc.

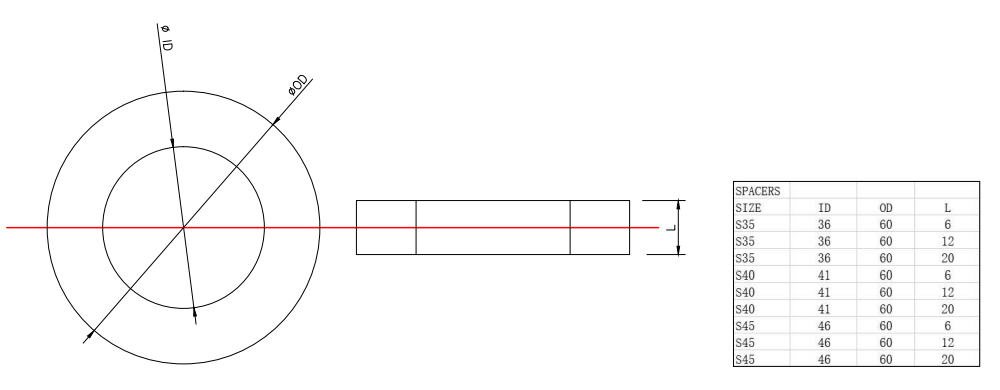

Precision Bucket Pin Bushing Shim Washer Machinery Bucket Bushings Shims

| Material | Carbon Steel | Part Name | Bucket Pin Bushing Shims |

| Surface | Smoothly | Application | Excavator,Wheel Loader etc |

| MOQ | 500pcs | Suitable Model | All Brands |

| Color | Zinc Plated | Loading Port | Xiamen,China |

| Specification | Customized | Payment Term | T/T,L/C,Ali Trade Assurance,Western Union,Paypal |

| Packing | Plywood Pallet | Delivery Time |

25 Days after Confirm Order or Drawing |

The bucket bushing,boom bushing,arm bushing,H link bushing,track bushing are customized according to customer’s request.

It is quenching,heat treatment and series processes to make the pin more wear resistant.Doolin carries a different types of pins and bushings to meet your replacement part demands.

The pin and bushing and bosses are designed,produced and inspected for good performance

Doolin can supply a wide range of pins and bushings which suitable your machine smoothly.

The shims can adjust spacing on shafts and machinery.Using Carton steel have excellent strength and can be welded. Zinc plated finish adds a layer of corrosion resistance. Using Stainless steel shims are more corrosion resistance.

|

ID |

OD |

THICKNESS |

|

25.5 |

38.1 |

2 |

|

30 |

48 |

2 |

|

35 |

55 |

2 |

|

40 |

60 |

2 |

|

45 |

65 |

2 |

|

25.5 |

38.1 |

3 |

|

30 |

48 |

3 |

|

35 |

55 |

3 |

|

40 |

60 |

3 |

|

45 |

65 |

3 |

|

32 |

50 |

2 |

|

32 |

50 |

3 |

|

...... |

...... |

...... |

| 80x40.15x54 | 75x42x26.4 | 25.5*38.1*31.85 | 45.2*70*43 | 40.2*64*46 | 31*60*6 | 46*60*12 |

| 90x45.15x54 | 85x47x26.4 | 25.5*57*31.85 | 40.2*70*43 | 40.2*64*70 | 31*60*12 | 46*60*20 |

| 100x50.15x54 | 85x52x26.4 | 35.2*70*56 | 30.15*57*31.85 | 40.2*76.75*74.25 | 31*60*20 | |

| 120x60.15x60.3 | 100x62x32.4 | 35.2*70*60 | 31.75*57*31.85 | 45.2*76.75*48.5 | 36*60*6 | |

| 130x65.15x60.3 | 100x67x32.4 | 35.2*70*38.1 | 38.3*70*38.1 | 45.2*76.75*74.25 | 36*60*12 | |

| 140x70.15x60.3 | 115x72x32.4 | 35.2*70*50 | 38.3*70*50 | 40.2*90*63.4 | 36*60*20 | |

| 160x80.15x73 | 115x82x39.4 | 40.2*70*44 | 65.2*101.6*89 | 35.2*70*48 | 41*60*6 | |

| 180x90.15x85.7 | 130x92x45.4 | 40.2*70*50 | 45.2*70*50 | 40.2*70*48 | 41*60*12 | |

| 200x100.15x98.4 | 150x102x51 | 40.2*70*56 | 25.5*57*50 | 35.2*70*28.65 | 41*60*20 | |

| 220x110.15x98.4 | 150x112x51 | 45.2*70*36 | 25.5*50*50 | 40.2*70*28.65 | 46*60*6 |

Bushing Process

1. Forging the bushing material

2. Producing according to customers’ requirements

3. CNC grinding

4. Dig oil slot,and drilling

5. Heat Treatment,the degree will reach to thousand Celsius,then make the bushing by high strength

6. After strength,go next process tempering

7. Grinding inside and outside product

8. Spray anti-rust oil,and package in the workshop

Please send the measurements to our sales team email info@doolincm.com.

If we have received your information,then we can confirm what you need correctly.

Tags :